Scrap shears

SCRAP SHEARS WITH LATERAL PRECOMPRESSION BOX AND VARIABLE ANGLE

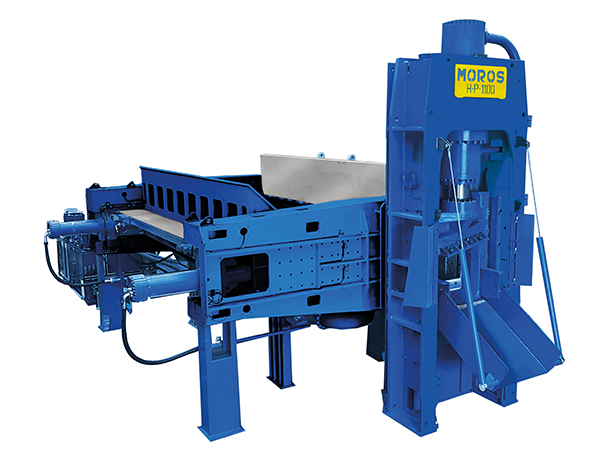

H-P

Productivity, reliability and efficiency

The variable angle system allows it to work with very tough, structural or voluminous scrap metal which no other scrap shear is capable of processing.

The enormous advantajes provided by lateral side compression result in an increase in production.

The latest technologies applied in control hydraulics and electronics allow the efficient use of power resources, making de H-P range a very profitable machine per tonne produced.

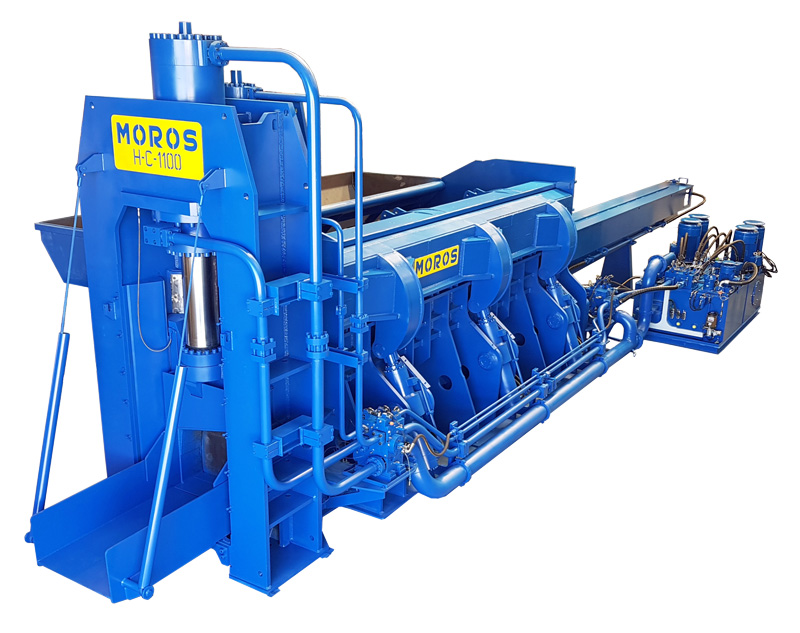

SCRAP SHEARS WITH LATERAL PRECOMPRESSION

SCRAP SHEARS WITH PRECOMPRESSION WINGS

GUILLOTINE SHEARS

H-M

Developed for the processing of large objects that do not require precompression.

Offers the possibility of using different methods for feeding the scrap metal into the head such as hydraulic pushers or push feeders.

ALLIGATOR SHEARS

for a lifetime

ALLIGATORS SHEARS TO CUT METALS

H-M-10

Manufactured with the same high quality standards of large scrap shears.

Possibility of adjusting blades and programmable automatic operation.

H-H-11

This shear has been designed to separate and clean metals. It allows non-ferrous and other materials on fittings to be separated and obtain higher yields from the recycling process.

H-K-15

Fast shears to worlk with non-ferrous materials and process large objects such as car radiators.

Availability of an inclinined version which automates the cutting process, increasing safety and productivity.

STEEL CUTTING MACHINES

H-J-15

Designed to work both with ferrous nd non-ferrous materials, thanks to the incorporation of a system which allows the cutting speed to be adjusted.

H-F-30

Reinforced to process ferrous materials.

Includes a “crusher” on the jaw side to process voluminous objects.